Your Cover, Our Care

Production of Roldeck® Covers

In Pelt, Belgium, is our modern production facility of over 10,000 m², where we passionately manufacture high-quality pool covers. From precision cutting of slats to assembling motors and thorough product testing – our dedicated team and high-tech machines guarantee the highest quality at every step of the production process.

- 001

Made in Belgium

Our production facility in Belgium meets the highest quality standards and safety regulations, resulting in reliable and durable products.

- 002

Custom Made

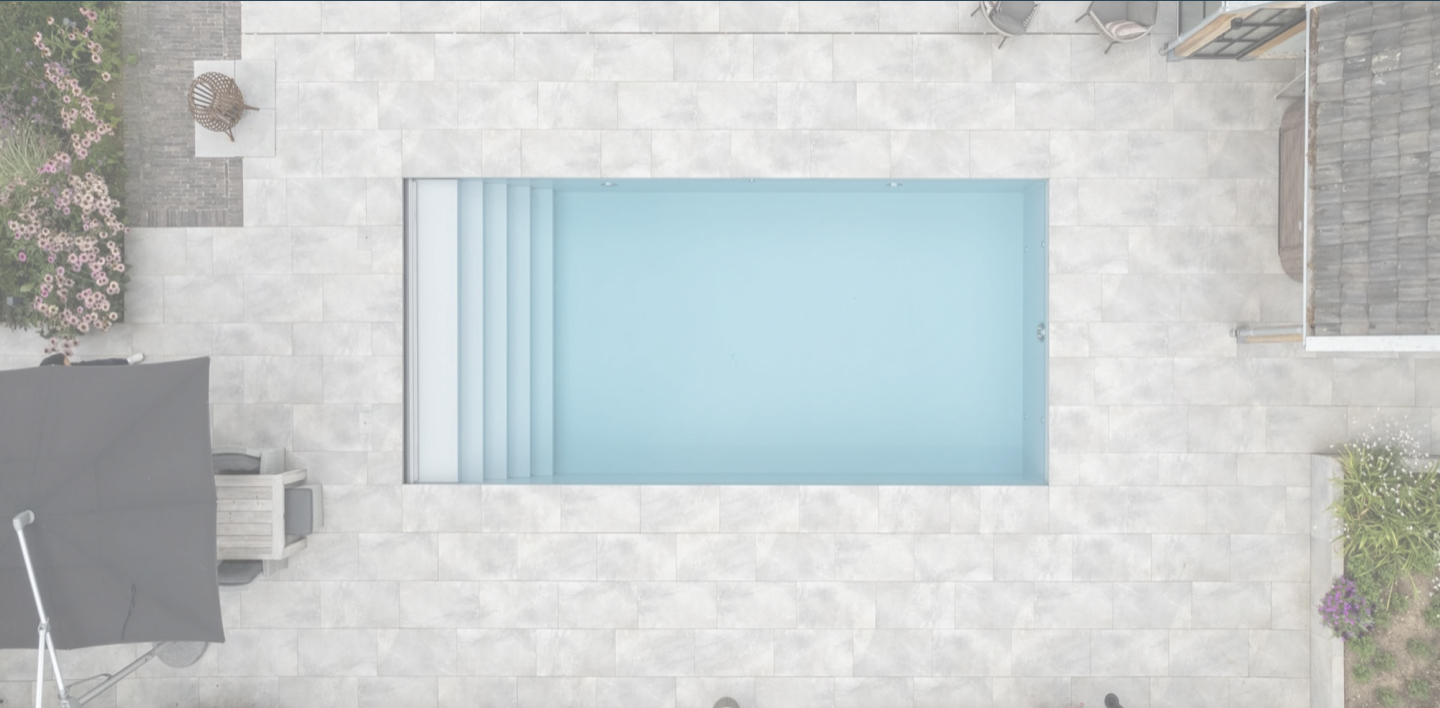

Whether it's a round, rectangular, or organically shaped pool, every Roldeck® cover is custom made according to the specific requirements of the project.

- 003

More than 50 years of experience

With over half a century of continuous presence in the pool industry, we guarantee the quality and innovation of our products, supported by our in-depth knowledge and experience.

- 004

Sustainably produced

With 1,220 solar panels on our factory, we actively contribute to sustainable production processes, minimizing the ecological impact of our products.

The production process in steps

Your order has been received!

The process starts with entering your order into our ordering system. Once the order is processed, it will be scheduled for production. The specifications—such as slat type, color, and dimensions—are forwarded to our production team. They begin by picking the right materials and components to create your pool cover.

Cutting the slats to size

The slats are precisely cut to size to ensure the cover fits the pool as completely as possible. After cutting, the slats are cleaned with high-pressure air to remove any residue. They are then clicked together to form a long strip.

Attaching the end caps

The end caps are inserted into the PC slats under the correct air pressure, along with a silicone sealant. For PVC slats, the connection is made using ultrasonic welding. Both processes ensure an airtight and watertight seal of the slats, which is essential for the long-term durability of the cover. In addition, humidity and condensation inside the slat chambers are minimized.

Assembly of the shaft

While the slats are being produced, another department assembles the tubular motor. The shaft is made to the correct width and, if ordered, the tubular motor is integrated into it. The slats are then attached to the shaft using straps and rolled up.

Testing phase

At Roldeck®, quality comes first. That’s why every Roldeck® cover is thoroughly tested before it leaves the factory. This ensures the durability of the slats and the proper functioning of the motor. It allows us to guarantee that your cover is safe and reliable for daily use.

Preparing for transport

Once production is complete, the cover is carefully packaged as a ready-to-assemble kit, including all necessary parts and materials, making it ready for transport. Our logistics team ensures your cover is delivered quickly and safely. Orders placed before 12:00 p.m. are shipped the same day, while later orders are processed the next working day.

Visit our production facility

Curious about the production process of a Roldeck® cover? We would be happy to welcome you for an exclusive tour of our production facility in Pelt (BE). Simply request your tour via the contact form and discover the quality we offer!