The Origins of the First Automatic Slatted Cover

The Story of Roldeck®

In 1973, the foundation was laid in Valkenswaard, Brabant, for what would later become a leading company in the swimming pool industry. Two brothers, Tini and Frans de Nier, joined forces: one a technical all-rounder, the other a born commercial talent. Driven by their shared passion for innovation and craftsmanship, they aimed to build nothing less than the most beautiful and the best swimming pools. But how do you build the best pool without the best components?

The early years

The seed for Roldeck® was planted in 1973 when Tini de Nier started his own business. In 1979, his brother Frans de Nier joined the company. However, the Netherlands was a small market, and the supply of quality products for pool construction was minimal. In America, of course, it was quite different. It is therefore no surprise that the U.S. became one of our main sourcing countries. We imported pools, chemicals, and cover systems to resell them. This is where the seed for Roldeck® was planted.

The development of Roldeck®

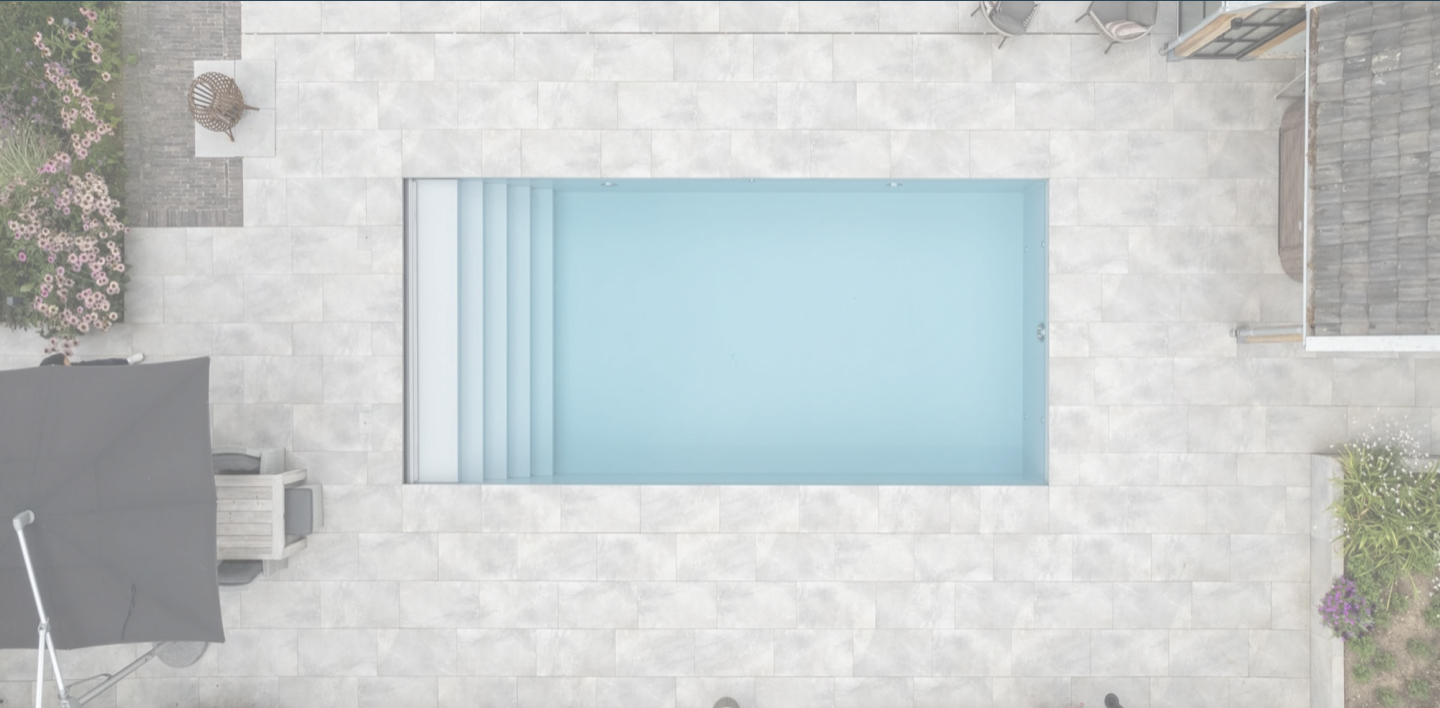

The imported products, including the covers, did not always meet the high quality that Roldeck® strived for. When it became clear that the desired quality was not even available on the market, it was decided to develop and produce an innovative cover solution in-house. This led to the creation of the first fully automatic slatted pool cover: the Roldeck®. The system offers a combination of simplicity, aesthetics, safety, and durability, allowing pools to be opened and closed automatically.

Opening of the Pool Information Center

Even after an expansion, the building at De Vest 24 became too small. In 1991, construction of a new building at De Vest 50b followed, including the Pool Information Center. At that time, it became the largest pool showroom in Europe, featuring both indoor and outdoor pools. From this location, customers were advised on pools and covers, both nationally and internationally.

Development of the first tubular motor

In 2006, Roldeck® launched its first tubular motor, made of stainless steel, a compact and efficient solution after years of using external motors. Where previously cam and sensor motors were used, this innovation offered simpler installation and a sleeker design, without compromising on reliability. In 2008, the introduction of the plastic tubular motor RDIM80 followed, which offered even more installation possibilities. Both developments contributed to the further technical advancement of pool covers.

Move to the Dragonder

In 2007, Roldeck® moved to a new building at Dragonder in Valkenswaard. The growing production capacity at De Vest had reached its limit, which led the De Nier brothers to decide to build a modern facility that would allow for further development.

First Polycarbonate Slat on the Market

n 2008, Roldeck® introduced the first polycarbonate slat to the market, an innovative step in improving pool covers. The choice of polycarbonate was a direct response to the increasing heavy hailstorms and the stricter requirements from insurers regarding hail damage. In the HQ (High Quality) slats, the UV-blocking layer is incorporated into the raw material, making them not only more resistant to wear but also to extreme weather conditions and high temperatures. The result is a durable and reliable pool cover that contributes to long-term protection and ease of use.

Introduction of the Roldeck® EasyCover

In 2010, the introduction of the Roldeck® EasyCover marked an important step in the evolution of pool covers. This above-ground system offered a clever solution for pools with limited space around them. With its sleek and discreet end supports, it not only created a neat and tidy appearance but also provided greater accessibility for a wider audience thanks to its easy installation and automatic operation.

Opening of New High-Tech Production Facility

Ultimately, it proved more practical to centralize the production of both Roldeck® and Monoblocks at one location. In 2010, Starline opened a high-tech factory in Pelt, and in 2011, the production of Roldeck® also moved there. This logistical decision resulted in more efficient delivery and production of both Monoblocks and Roldeck® systems. With a production area of 65,000 m², Starline has since continued to innovate and focus on sustainable and responsible production.

Launch of New Control System

In 2013, the new RD2013 control system was introduced, simplifying and expanding the operation of Roldeck® cover systems. The system consists of a control panel, the multifunctional S-Switch control panel, and a remote control. The S-Switch panel displays essential infoIn 2013, the new RD2013 control system was introduced, simplifying and expanding the operation of Roldeck® cover systems. The system consists of a control panel, the multifunctional S-Switch control panel, and a remote control. The S-Switch panel displays essential information such as the status of the Roldeck®, pool lighting, and (optionally) water temperature, making operation and programming easy. With additional connection options and functions,rmation such as the status of the Roldeck®, pool lighting, and (optionally) water temperature, making operation and programming easy. With additional connection options and functions,

Launch of Solar Eclipse®

In 2019, the Solar Eclipse® was launched, a new generation of slats that resulted from years of innovations with models such as the PC60, PC63, PC66, and PC83. What makes the Solar Eclipse® special is the unique integrated UV-blocker in the polycarbonate slats. This protects against discoloration and aging caused by sunlight, allowing the slats to maintain their quality and appearance much longer. Thanks to its high buoyancy, excellent insulation value, and algae-masking properties, the Solar Eclipse® quickly became a great success for Roldeck®.

Acquisition by CF Group

In 2022, the acquisition of Starline Group, including Roldeck®, by CF Group marked an important step in its growth. CF Group, a leading European manufacturing and distribution group in the pool industry, active in over 40 countries with 1,200 employees worldwide, offers strong synergies and new market opportunities through this acquisition. Especially in the German-speaking regions, the company strengthens its leadership position and consolidates its presence in the Belgian, Dutch, and European markets.

Want to know more about Roldeck®?

Download the brochure or ask your question via the contact page.